Multi-Cavity Compression Molding

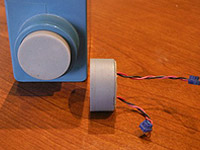

C & M Rubber Co. produced this silicone rubber encapsulated ultrasonic sensor assembly for a customer in the manufacturing/packaging industry. This project presented two unique challenges. First, the face thickness of the rubber sensor body needed to be held to a tight ± .003″ tolerance to minimize distortion of the ultrasonic frequencies. Second, to maintain the high sheen required on the face of the rubber part, no mold release agent could be used.

C & M Rubber Co. produced this silicone rubber encapsulated ultrasonic sensor assembly for a customer in the manufacturing/packaging industry. This project presented two unique challenges. First, the face thickness of the rubber sensor body needed to be held to a tight ± .003″ tolerance to minimize distortion of the ultrasonic frequencies. Second, to maintain the high sheen required on the face of the rubber part, no mold release agent could be used.

Working with customer specifications, our engineers developed precision tooling that would keep the part within the tight dimensional tolerances and have the lubricity to release it with no sticking. Utilizing a 25-ton hydraulic press and silicon rubber with a 30±2 Duro Shore A hardness, we executed a multi-cavity compression molding process to encapsulate the heater and sensor assembly. A manual deflash and inspection process verified that desired high gloss finish was achieved and the tolerances were within specification.

At C & M Rubber, we manufacture this part on an ongoing basis within a 1-2 week turnaround and deliver stock just-in-time to the customer. For more information on this project or to learn how our encapsulation molding expertise can improve your application, request a quote today.